The Apalachicola Bay System Initiative (ABSI) hatchery team has had a busy spring and summer! The hatchery staff, Shannon Kirk (technician), Joe Rocco (manager), and interns Morgan Hawkins and Benton Jaco have successfully completed ABSI’s first oyster spawning and setting.

The Apalachicola Bay System Initiative (ABSI) hatchery team has had a busy spring and summer! The hatchery staff, Shannon Kirk (technician), Joe Rocco (manager), and interns Morgan Hawkins and Benton Jaco have successfully completed ABSI’s first oyster spawning and setting.

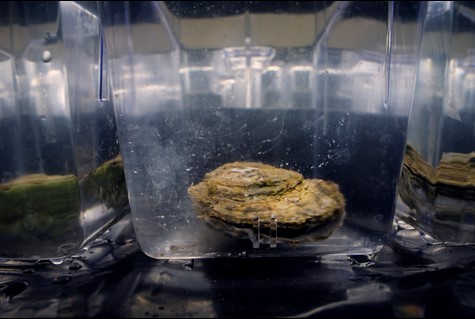

To begin the spawning process, mature adult male and female oysters, referred to as ‘broodstock’ were collected from Apalachicola Bay. These animals were cleaned thoroughly the day before the spawn to prevent the eggs and sperm from being contaminated by other organisms growing on the shells. On the morning of the spawn, each oyster was placed in its own tank and left to acclimate to the water temperature for 30 minutes. Once successfully acclimated, the oysters were stimulated to spawn through a process called thermal cycling, which alternates 30-minute cycles of cool and warm water to jumpstart the spawning process. Male oysters spawn by releasing a steady stream of sperm while female oysters puff out clouds of eggs. Once both the males and females released their respective gametes (reproductive cells), the hatchery team collected eggs from multiple females and added sperm from multiple males to fertilize them. The fertilized eggs were then stocked into larval tanks.

While in these tanks, the larvae were checked every day to make sure they were healthy and swimming. Their diet consisted of a mix of concentrated microalgae twice a day. To promote a clean environment to grow in, the larval tank water was changed every two days. Hatchery technicians collected the larvae on sieves (fine mesh strainers) and separated the smaller larvae samples from the larger, faster growing larvae. Once separated, the larvae were restocked into clean water filtered to 1 micron (µm), one of the smallest filter possible to remove any outside sediments or organisms. About two weeks later, the larvae started to develop eye spots, which is also known as the pediveliger stage. During this phase, the team moved the larvae to a setting tank filled with oyster shells. These tanks were then covered with a tarp to keep it dark and the larvae were left to set (to set means to settle on a hard substrate, such as oyster shell) for three days. Larvae are photosensitive and tend to swim away from the light. By keeping the tanks dark, the oysters were able to set throughout the water column in the tank instead of simply settling at the bottom. Once the larvae attach to oyster shells or other hard substrates, they become known as spat. The spat were then fed fresh algae from incoming seawater flowing through the tanks.

While in these tanks, the larvae were checked every day to make sure they were healthy and swimming. Their diet consisted of a mix of concentrated microalgae twice a day. To promote a clean environment to grow in, the larval tank water was changed every two days. Hatchery technicians collected the larvae on sieves (fine mesh strainers) and separated the smaller larvae samples from the larger, faster growing larvae. Once separated, the larvae were restocked into clean water filtered to 1 micron (µm), one of the smallest filter possible to remove any outside sediments or organisms. About two weeks later, the larvae started to develop eye spots, which is also known as the pediveliger stage. During this phase, the team moved the larvae to a setting tank filled with oyster shells. These tanks were then covered with a tarp to keep it dark and the larvae were left to set (to set means to settle on a hard substrate, such as oyster shell) for three days. Larvae are photosensitive and tend to swim away from the light. By keeping the tanks dark, the oysters were able to set throughout the water column in the tank instead of simply settling at the bottom. Once the larvae attach to oyster shells or other hard substrates, they become known as spat. The spat were then fed fresh algae from incoming seawater flowing through the tanks.

After another two weeks of spat growth, the hatchery technicians began sorting the oyster shells full of newly settled spat. Less dense shells that held 1-6 spat samples were sorted into aquaculture cages (150 spat per cage) which were placed on ABSI’s restoration experiments to assess their survival and growth. These had fairly low numbers of spat to avoid overcrowding as the oysters grow. The rest of the shells (with more than 6 spat) were placed in biodegradable mesh bags (50 shells per bag) and placed on the substrate at the end of each experimental site. This less precise approach will be used to assess the value using bagged spat on shell as a restoration method.

Currently, the ABSI hatchery team has set their next stock of oysters and are monitoring their progress. These will also be deployed on the restoration experiments.