We continually make improvements to the FSUCML facilities to support our mission and always with an eye toward reducing our ecological footprint while enhancing safety. Here are some of the most recent advancements.

On the Waterfront

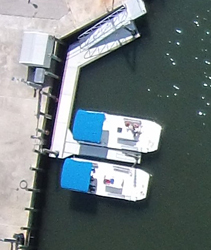

We have a new Bellingham Marine floating dock on the east side of the boat basin adjacent to the concrete bulkhead that provides docking space for small boats and a gangplank for pedestrian access from the bulkhead to the new dock, which is safer and more convenient for loading and unloading both passengers and gear. We also "repurposed" one of the old pontoon boats to build a second floating dock on the west side of the boat basin (Coleman just won't throw anything away that has any life left in it). To enhance dock safety and decrease power usage, Jim Stephens (Director, Campus Facilities), replaced old lights on the dock with new ones sporting the latest energy efficient LED technology. The low profile lights come on automatically at dusk and are triggered by motion to shine with greater intensity.

Improving Water Quality at the Marine Lab

Water delivery at the FSUCML has long suffered from several issues: (1) old steel pipes that were corroded and caused water staining; (2) chlorine delivery so high as to render "potable" water undrinkable; and (3) chlorine delivery occurring where it was not required (e.g., to outdoor spigots used for irrigation and washing gear, vehicles, and boats -- much to the detriment of landscape plants, seagrass beds off the lab, and the groundwater receiving the chlorinated water) at considerable cost.

All that changed recently with the installation of new PVC main water lines that improved water quality and flow by elimination of the internally rusted circa 1967 steel water lines. Rather than having all water lines connected to the chlorine delivery system, we realigned them to have some deliver water to the chlorine system, supporting areas requiring potable water (e.g., bathrooms, kitchens, lab benches), and other lines deliver untreated water to designated outdoor spigots. Chlorine use was further diminished by installing an electronic post chlorinator pump that increased the precision of chlorine delivery. Between these two "fixes", overall chlorine use decreased by 85%.

With the new alignment of water came installation of an irrigation system (thanks to FSU Facilities Grounds Maintenance staff) for the landscaped beds around the lab, allowing us to water more strategically and conservatively.

FSUCML Connects With the 21st Century

In 2006, when Coleman first started at the marine lab, connectivity to the world was through a dial up connection and the first two postdocs ate all the available bandwidth. While connectivity improved between then and now, the most recent upgrade allowed FSUCML to join the rest of FSU in the 21st century through a major network cohesion plan. It provides significantly increased bandwidth; improved wireless network that broadcasts throughout the FSUCML campus; and added power-protection and off-site backup for all our files. Mike Repchak, Technical Support Specialist in the Office of the Vice President for Research (OVPR), oversaw every detail of the project, from concept to installation. We are in great shape now, and very grateful to the OVPR.

And Elsewhere Around the Lab

On the main laboratory building, we used funds from FEMA to replace the 1968-era wooden hurricane shutters with hurricane accordion shutters that can withstand high velocity (up to 150 mph) winds.

And in the guest house, the front bedroom that once had three sets of old metal prison-issue bunk beds and a recalcitrant sliding glass door now sports three new sets of wooden bunk beds and a single stationary window that dramatically increased the efficiency of heating and cooling the space. Thanks to Dan Overlin, resident carpenter, for his creativity and woodworking ability. More bunk bed replacements are in our future.